What is 3D Printing Good For?

Overview

There are a lot of folks out there who are interested in 3D printing, but then they look at one of the many sites of free models like Printables and see a lot of silly tchotchkes that seem like a waste of plastic and space, or cheap things they can already buy cheaply like pen holders. Recently someone asked the following question on Reddit.

What type of people need a printer?

I’ve been sitting on the idea for 4 years to buy a 3D printer but every time I decide against it. In my mind, If I need a small part for something, I’d rather just buy a quality version of it instead of a brittle plastic one. I considered it for small tools for locksmithing but … why would I? I can just buy the real thing and have it last years. I think it’s useful for intense D&D players or cosplayers but that’s not me. And every time i research useful things to make with a printer it’s always stuff like “pen holder, mini plant holder, phone case, remote mount”. Which I have to admit are pretty lame for a $200-$500 machine and materials. Everything I read can be found at a dollar general. But they have to be popular for a reason right?

So who consistently uses a 3D printer? What do you personally use it for that isn’t just a holder for a small thing? Can you justify printing something over just buying it?

It’s a totally reasonable question, and one that I’ve answered variations of a bunch of times. This post assumes you don’t know a lot about 3D printing and are wondering if there’s any “real” value to getting one.

First though, let’s address some conceptual housekeeping so that we have a common understanding going forward.

Terminology

When people say “3D Printing” what they usually mean is “FDM” (Fused Deposit Modeling) printing. This is where you’ve got a spool of filament that is gradually extruded through a hot nozzle and builds up a print layer by layer. There are countless practical uses for this, but it’s not good at printing fine details (sub millimeter).

However, at the consumer level there’s also “Resin” printing, which uses light (laser or LCD) to strategically harden layers of goo. This is a messier process that involves dealing with some nasty chemicals but produces pieces with incredibly fine detail. This is great for things like D&D Minis.

Plastic types

short version: PLA, ABS, and TPU are 3 of the many filament types available, and I’ll be referring to them later. If you don’t care about details skip this bit.

PLA is the most common filament. It’s made from Polyactic Acid which is technically “plant based” but even when there aren’t additives it’s not something that’ll break down quickly in the environment or even in a composter.

ABS is what’s most commonly used in injection molding, but some home 3D printers can print with it too. As a rule of thumb, if you buy anything plastic it’s probably made with PLA. It’s got a lot of good properties. However, it releases some truly nasty Volatile Organic Compounds when you heat it for printing that you really shouldn’t breathe. The biggest reason to use it is that it’s got enough heat resistance to be stuck on the dash of a hot card in summer and not melt. There are better alternatives, and many aren’t as nasty.

TPU is a “rubbery” filament that can be used for gaskets or things where flexibility is important. It comes in multiple levels of… floppyness. Technically this is called the “Shore Hardness”. I don’t know why. What’s important, is that this is a very useful option for consumers The softer it is, the harder it is to print.

Resins Unfortunately this is not an area I can really speak to with authority. I know there are many available, and that it’s easy to mix pigment and sparkles into the clear resin to make something a particular color, but most folks seem to use it to print grey things that they paint afterwards.

Misconceptions

Strength

For most things you’re likely to want to print FDM prints are more than strong enough. Especially when it comes resisting compressive forces. They’re less good at resisting being pulled apart. However, we’re talking over 900 Newtons of force to rip a standard PLA (the most common filament type) print in half.

Lasting Power

3D prints last a LONG time. Despite being “plant based” the things you print with PLA are going to outlast you. It may fade in sunlight, but that’s true of most plastics. PLA is NOT good in water, but other filaments are.

Degradability

Multiple filament makers promote the fact that PLA is “Plant Based”. It would be equally accurate to say that petroleum based plastics are also “Plant Based”. Some filaments say they can be composted. Alas, this is only technically true. It would have to be an industrial composting facility which has significantly higher temperatures than your back yard, and even there it’s so problematic that they generally won’t accept them.

PHA filament from ColorFabb is the only one I’m aware of that is truly compostable, even in a home composter. However, at the time of writing (Feb, 2024) it’s pretty new, not cheap, and very few people have actually worked with it.

Filament Reusability

It’s technically possible to re-melt filament from old prints, but in practice it’s surprisingly expensive and non-trivial. I have a blog post explaining how to recycle 3D prints.

Food Safety

Even if you print with a food safe filament, FDM printed items are not food safe. The problem is that bacteria can hide between the layer lines and resist cleaning. Using a food safe filament for things like organizing your cutlery drawer is fine though, because the print is never going to come into contact with food.

Printing Minis

People who play tabletop games like D&D or Warhammer generally like to have miniatures representing their characters or troops. Your common FDM printer is not going to be good at this. They just can’t reproduce the level of fine detail you need. You need a Resin printer for this. The good news is there are some really affordable, good quality ones that can easily print most minis.

What’s it good for?

If your primary desire is to print gaming minis, a cheap resin printer from a reputable maker will pay for itself in a week. There are tons of excellent mini designers out there with very affordable models. You’ll never need to model your own. Just be careful about getting one with a big enough print plate for the things you want to print.

For everything else though…

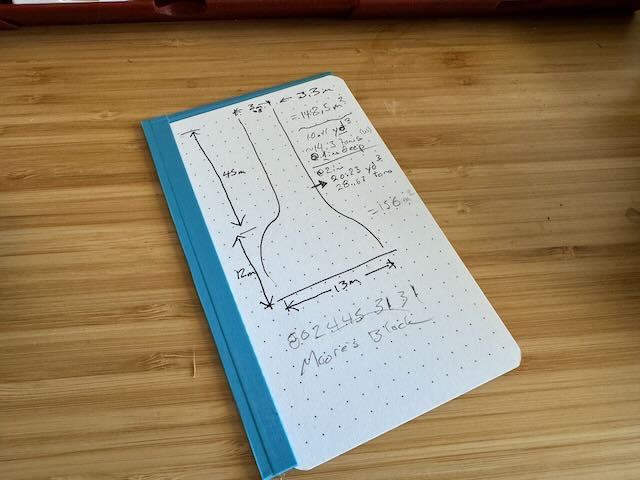

It depends on your willingness to learn how to model things yourself. Simple shapes are easy with tools like Tinkercad, but the more you get into this the faster you’ll get frustrated with how hard it is to do anything but the simplest of shapes. Learning real CAD (Computer Aided Design) software is a fair amount of work, but it’s absolutely worth the time investment. There aren’t many good options between “beginner” and “professional”. The most popular professional tool for amateurs is Fusion 360. It has a free plan, and there are tons of video tutorials that’ll help you learn it fast.

If you’re not interested in spending time learning a professional level tool, then frankly I don’t think you should bother getting a printer. Tinkercad is fun and easy but incredibly limited and hard to do anything complicated with. Sites like Printables do have a ton of things you can download and print, but most of it is not anything you really need often enough to justify buying a printer. The big exception might be the ever-expanding Gridfinity organizational system.

Where 3D printing really shines though is not the stuff you can download and print. It’s the things you can’t buy, and sometimes the things that are unreasonably expensive to buy, or ship.

Fixing Things Manufacturers no longer value “high quality, well made” things that last a lifetime. Things are constructed as cheeply as possible, have no replacement parts available, and are rapidly abandoned by their makers. Things will wear and break in ways that shouldn’t require throwing them out and researching potential replacements.

If you know how to measure and model things you can make just about any plastic replacement part you need: replacements for worn gears, broken switches, lids, etc.. The only real restriction here is heat. If you need something that can survive the heat of a car on a hot summer day with full sun, then you’ll need some special filaments which require higher end printers and ventilation systems that aren’t easy or cheap to set up.

3D prints can also be used to make molds for poured metal parts like brass gears, or metal sculptures.

Prototyping Thinking about making a physical object for sale? Need a way to cheeply iterate on something in the real world? Maybe confirm that it fits and does what you expect before spending a lot on making a metal version? 3D printing’s great for this.

Solving Unique Problems This is where 3D printing truly shines. Once you learn how to quickly model your own things the possibilities for solving real world problems are endless. It’s hard to convey a sense of just how many things you can do, so instead I’ll give you examples of what I’ve used mine for in the following section.

How I use Mine

Non-exhaustive - and unordered - lists of things I’ve printed and hope to soon print.

Things I have printed

-

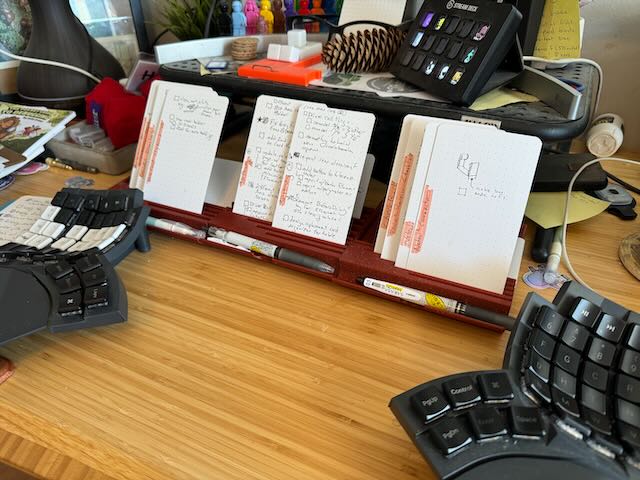

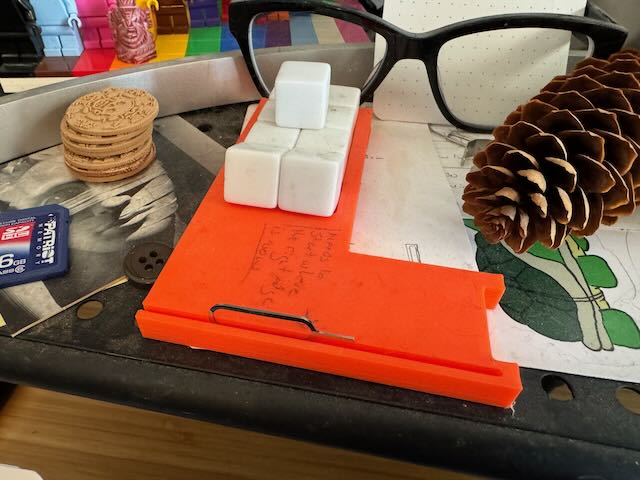

a custom system for managing notecards to help keep track of all my ideas

-

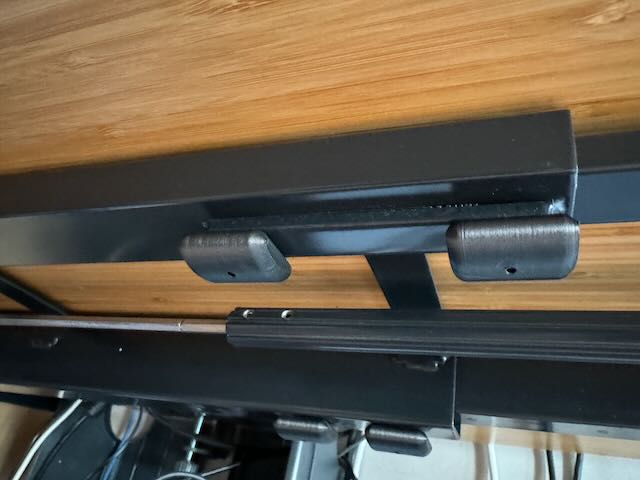

bolt covers to keep the bolts on the bottom of my desk from ripping my jeans, and pressing into my legs uncomfortably.

-

custom dividers and inserts for Milwaukee packout cases

-

things to organize my tool drawers: bit organizers, socket organizers, lots of Gridfinity things

-

a custom keyboard and trackpad holder to address a friend’s accessibility issues (palm rejection doesn’t work for him so laptops always think he’s mousing when he isn’t). Technically this is still in-progress.

-

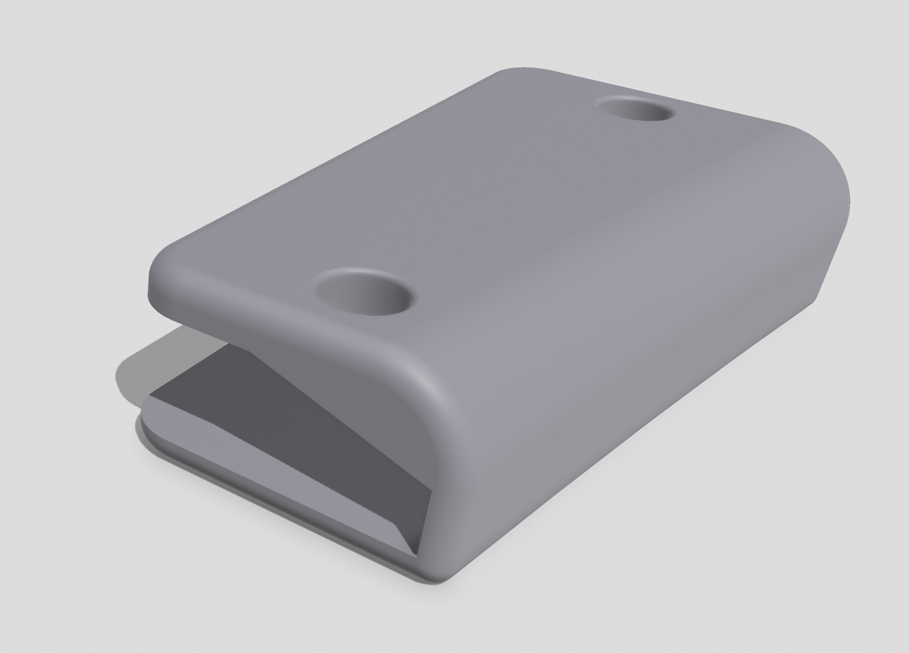

custom mounts for my split keyboard to attach to my desk so that the right half stops “going walkabout” while I’m trying to use it.

I’ve actually made two different versions of these to attach to two different desks and at different distances. One for myself, and one for a friend.

-

one for my friends desk with an longer curved & angled front because his keep sliding down the front edge.

-

custom dice trays, with leather bottoms that attach to the sides of my wooden lap desk, and then connect together with a rubber (TPU) gasket that holds them closed like a clamshell.

-

a valet tray that I use in our freezer because the weird silicone ice cube tray i use to make Tea Cubes has a habit of overflowing and leaving a creeping frozen brown in the freezer… or it used to.

-

Currently working on an adapter for my Dremel Drill press to allow it to mount the soldering iron I use for heat-inserts

-

custom organizers for board games with lots of pieces and / or cards

-

a custom organizer for games with lots of little tiny markers or dice that suck to put into or remove from those terrible little zip-lock bags they come in.

-

a custom pen/pencil holder that attaches to the side of the little side-table shelf thing that sits next to my side of the couch.

-

a custom single index card clipboard that fits in a pocket and allows me to write a note on one anywhere.

-

custom switch cover to install a switch in a big gaping hole in our ambulance.

-

more custom switch covers

-

a light box for photography

-

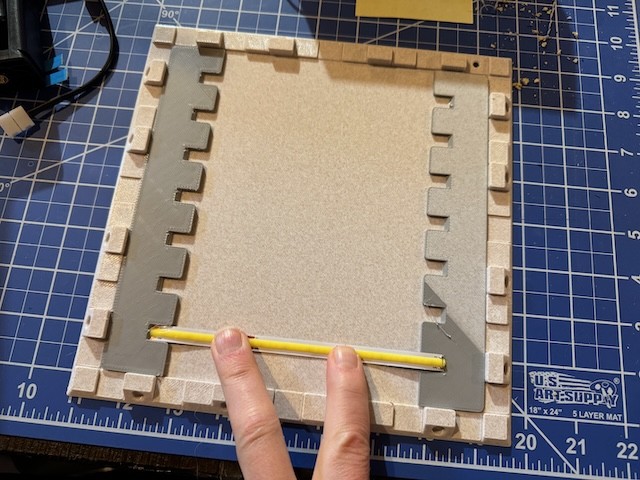

A jig for evenly spacing and aligning the LED strips for that light box.

-

A Micro Jib (video link) for photo and video purposes.

-

A jig for precision cutting of steel rods for the Micro Jib

-

A custom hole cover to protect wires from sharp metal edges

-

A Paper Towel holder mount

-

A special flexible plastic to adjust the seal on a CPAP

-

coasters

-

new discs for my disc binder

-

bookmarks that attach to disk binder disks

-

custom tool holders

-

adapter to allow me to use cheaper, easier to find HEPA filters with my printer enclosure

-

tons of mods for my 3d printing stuff. Everyone does this though.

-

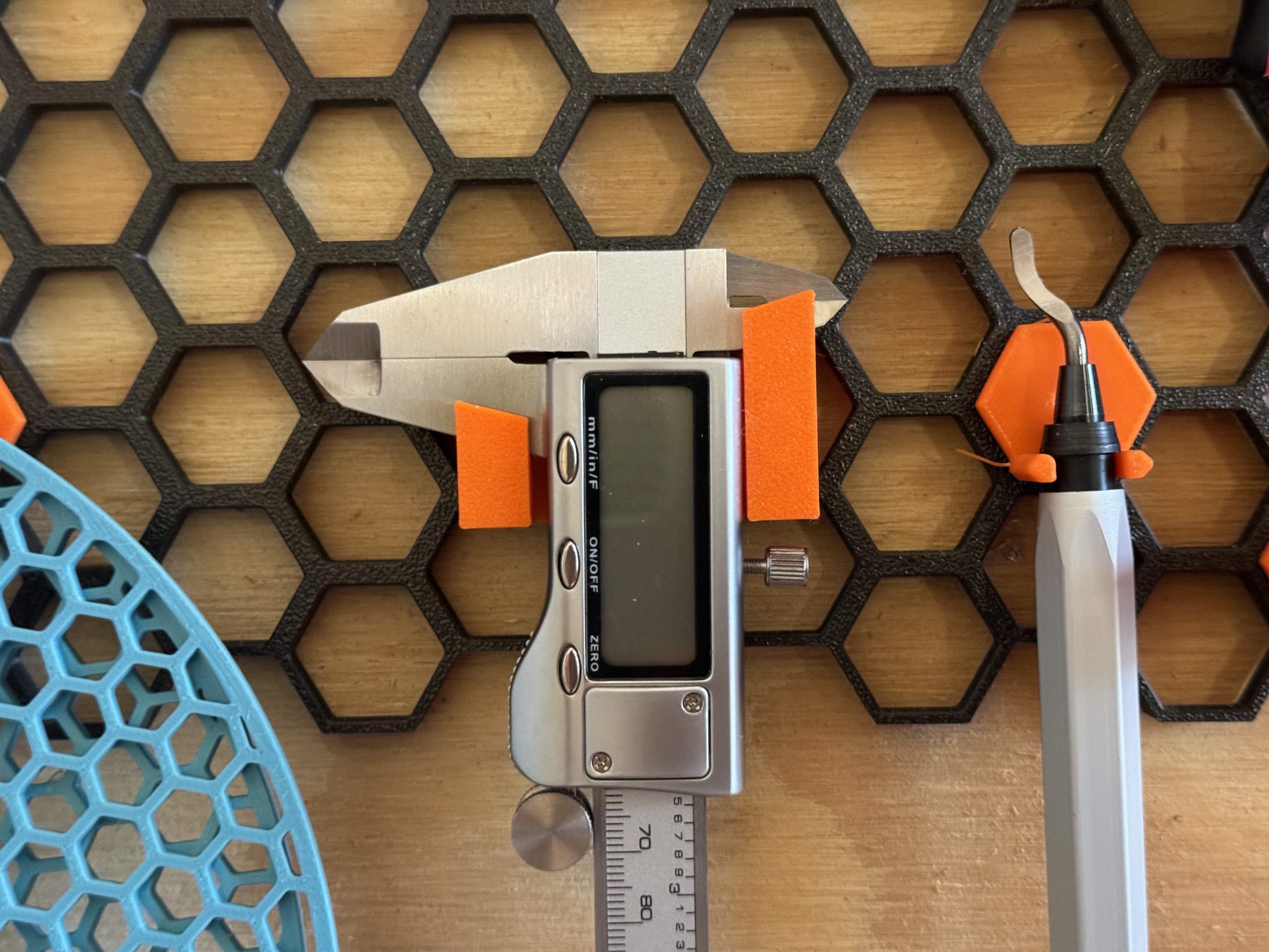

Tool holder wall (I went with the Honeycomb wall, might go with Multiboard if i revisit this.)

-

jigs for holding dice I laser etch.

-

jigs for holding other things.

-

magnet insertion tools

-

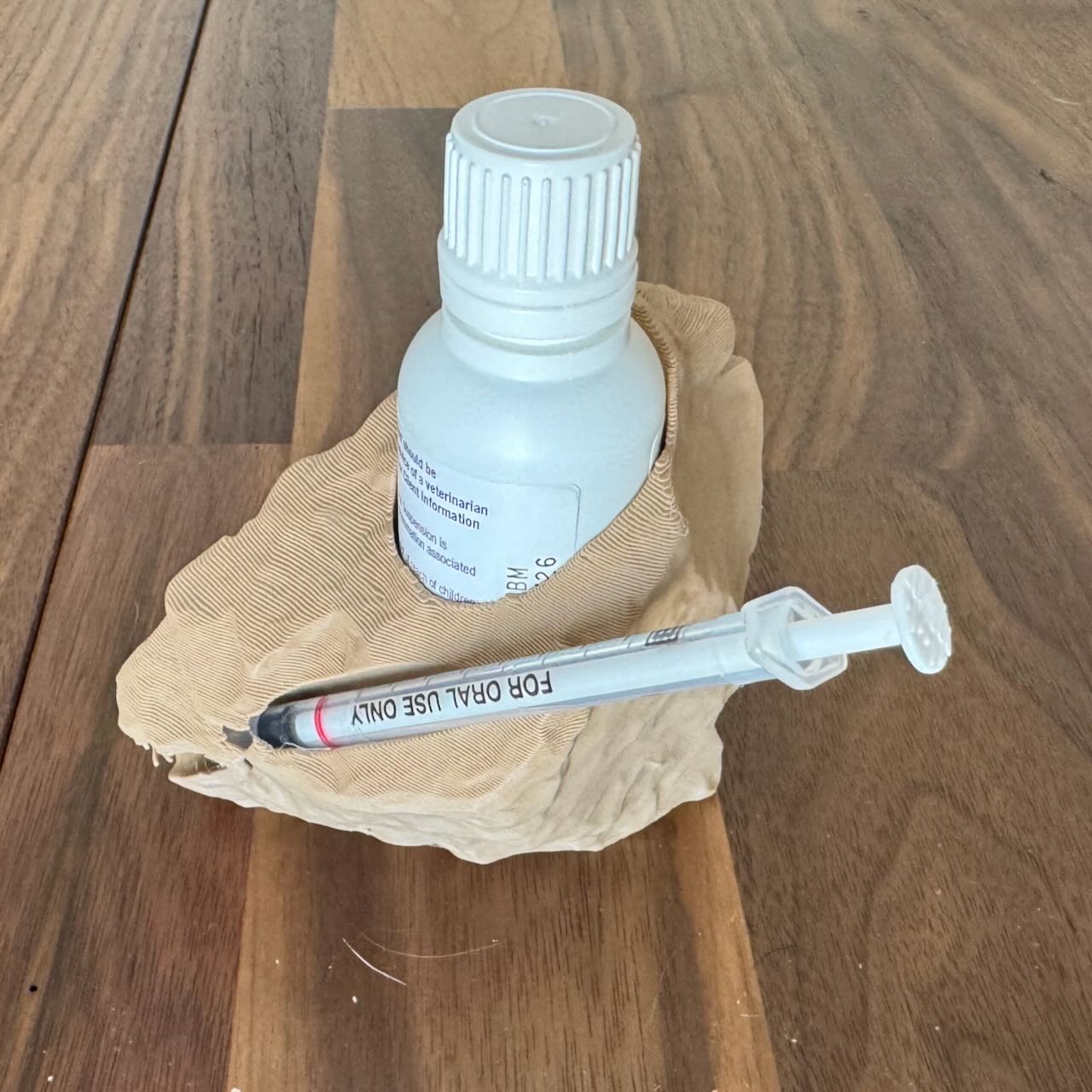

a fake rock with cutouts for holding a small bottle of medicine and a syringe.

-

A custom tool to facilitate cutting lids off of 5 gallon water bottles.

-

D&D Minis. These were on my last FDM printer and they were not very good.

-

Headphone hangers

-

Fixed a lamp. It fell over and the ring that held on the diffuser no longer fit. So I printed a replacement out of flexible filament.

Warning

If this post has convinced you to get a 3D printer, I must give you a warning before you do. Cheap FDM printers are, in my opinion, a pain-in-the-ass. I almost never used my first printer because it was a constant series of frustrations and poor quality prints. There are thousands and thousands of posts on reddit of people asking why their print has one of a hundred different possible problems. Getting a $200 (USD) printer dialed in to make great prints is possible, but it’s a lot of frustrating work that feels like your trying to read tea leaves.

My current recommendation (February 2024) is to get any of the printers made by Bambu Lab. The more you spend the more you’ll be able to do with it. The reason I recommend Bambu is because their printers are the closest anyone has ever come to making a printer that’s as easy to use as a Laser Printer. It’s not quite as easy yet, but it’s damn close. Getting a printer with an enclosure like their X1 Carbon (X1C) will make your life easier, because the ambient temperature has a significant impact on the quality of your prints. Unfortunately, the X1C + the multi-filament management system (don’t buy it without that) is like $1500, and then you’ll need to buy filament.

I use my X1C probably 3 times a week on average. I never print tchotchkes.

Feel free to ask me questions on Mastodon. I’m happy to help people out.